What is Machine Monitoring System?

—

Originally posted on: https://promanagecloud.com/what-is-machine-monitoring-system/

The manufacturing world is rapidly evolving, which means you either stay ahead of the competition or be left behind. But how do you do that? Well, by embracing technology, you can enhance efficiency and reduce downtime. This is where one critical innovation has become an integral part of the manufacturing industry: Machine Monitoring System.

This technology has quickly become stable in modern manufacturing practices since it drives significant production and operation efficiency improvements. But what exactly is a machine monitoring system (MMS), and what are its benefits? Our blog will delve into the details to offer insights into how these systems operate and how they can benefit your business.

5 Facts About MES That You Might Not Know!

Simply put, a machine monitoring system is a sophisticated tool designed to track and analyze the performance and health of industrial equipment.

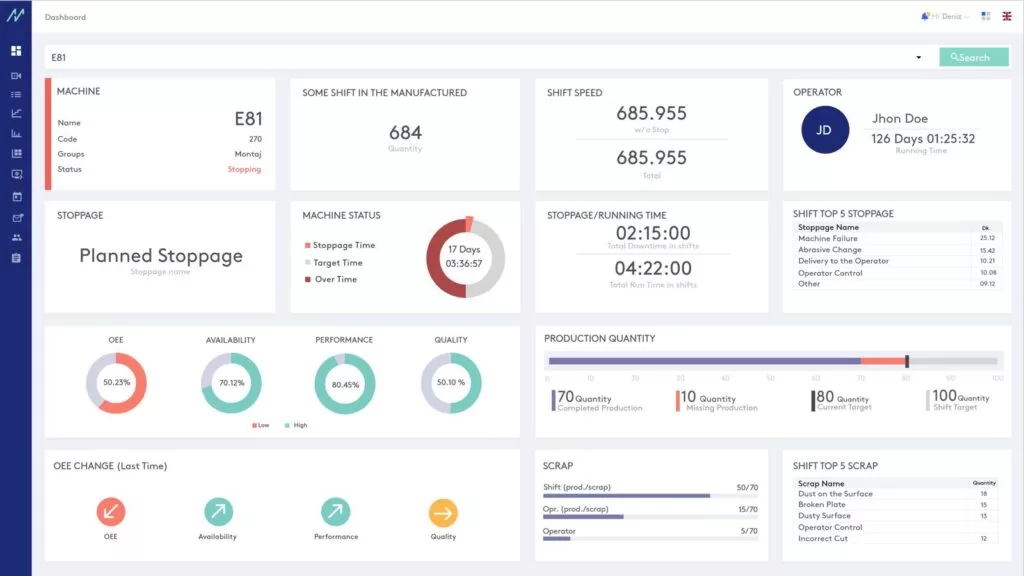

At its core, an MMS provides real-time data about machine status while helping managers, operators, and maintenance teams understand how well equipment functions. In short, it is an incredibly fast and scalable technique that helps turn manufacturing machine data into real-time insights.

A machine monitoring system is an advanced solution developed to continuously track and assess the performance and condition of industrial equipment.

How Does a Machine Monitoring System Work?

When it comes to function, there’s a clear-cut methodology for a Machine Monitoring System(MMS) centered around the continual collection and evaluation of data. If you want to get into details of how MMS works, you should know that it all starts with strategically installing various sensors on essential parts of a machine. Once installed, these sensors work their magic by gathering a broad array of data. This means anything from temperature fluctuation and vibrations to reasons for downtime and power usage. Next is the most crucial part: deciding if the sensors send the data to a centralized processing system through a wired or wireless connection. Once the data is collected, it is interpreted and converted into useful information.

Monitoring the machines prevents possible malfunctions.

Thanks to technological advancements, modern MMS solutions leverage the power of artificial intelligence and machine learning technologies to assess the data more meticulously. In fact, these advanced systems can forecast potential equipment failures and recommend timely maintenance measures by discerning patterns and trends beforehand. And that’s not all. Machine monitoring systems help operators quickly fix any detected irregularities by sending real-time notifications and updates. The result? Well, this perpetual oversight and anticipatory analysis help industries save money on expensive equipment repairs and replacements and also prolong equipment life along with many other benefits.

What is a Production Monitoring System?

Leveraging IoT for Enhanced Machine Monitoring System’s Functionality

Machine monitoring systems in manufacturing have become more sophisticated and effective through industrial IoT. After all, this technological synergy has helped overcome the many limitations associated with traditional information gathering. Overall, you can enhance industrial operations by equipping machine monitoring systems with IoT technology. For instance:

Machine Downtime Monitoring: The MMS allows you to easily monitor any machine downtime or inactivity. This can help you quickly address any underlying issues and reduce production interruptions.

Operational Flow Tracking: You can monitor the production process closely to ensure that each step proceeds smoothly and products are delivered on time.

Monitoring machines contributes significantly to production efficiency.

Quality Control Monitoring: The MMS can also help you track changes in product quality during the production process to maintain consistency and meet customer expectations.

Adopting IIoT in machine monitoring systems can help factories not only improve operational efficiency but also save costs and prevent potential issues before they arise. This integration is crucial for relieving the operational stress and maintaining seamless and productive factory operations in the modern industrial landscape.

ProManage Cloud machine monitoring system provides easy access to your data from anywhere.

Benefits of a Machine Monitoring System: Why Use It

Are you unsure whether you should implement a machine monitoring system? Well, the following advantages of using a machine monitoring system might change your mind:

Increased Operational Efficiency: This is the most lucrative benefit that makes many manufacturing businesses turn to MMS. This is because these systems excel at continuously tracking machine performance and identifying all of the areas where resources are not being used optimally. Pinpointing inefficiencies paves the way for smarter resource use and naturally cuts down energy bills and operational expenses considerably.

Advantages with MES MOM in Manufacturing

Enhanced Predictive Maintenance: Another benefit is the real-time data from monitoring systems. It helps make it a lot easier to forecast potential breakdowns. This means you can easily schedule repairs during off-peak hours to keep your production line moving smoothly without unexpected halts.

Improved Product Quality: This is an important benefit that no manufacturer should ever overlook. After all, constant monitoring checks that machines operate precisely as they should. This vigilance reduces the chance of producing defective goods, ensuring that your product’s quality consistently meets or exceeds standards.

Safety Enhancements: Did you know these systems help make the workplace safer by quickly detecting malfunctioning equipment before it can cause harm? It’s better to act now before it is too late. After all, this proactive approach to safety keeps your staff protected and can prevent costly accidents.

Waste Reduction: This is an often overlooked benefit of a machine monitoring system. By optimizing machine use and reducing the frequency of errors, monitoring systems also cut down on material waste. Less waste means lower costs and less environmental impact, aligning your operations with sustainability goals.

Real-Time Notifications: One of the most crucial features is that real-time alerts keep you informed the moment issues arise. Immediate notifications allow swift action to resolve problems, minimizing potential damage and downtime.

In short, adopting a machine monitoring system can boost operations’ efficiency and support a safer, more productive, and cost-effective manufacturing environment. With these “much-needed” systems in place, you can enjoy peace of mind knowing that your operations are under constant surveillance, poised for quick correction, and optimized for the best possible output.

FAQ for Machine Monitoring System

What is a Machine Monitoring System?

System in short is the real-time data gathering solution that platformizes the period that a machine operates as well as the productivity and service information. It brings information from many sources, develops them, and shows them easily to ensure, in particular, producers to enhance their manufacturing productivity and make sound decisions.

How does the system work?

The system operates through the deep connection of the devices to the machines using IoT-based services or software integrations to provide useful metrics out of which cycle time, downtime, energy usage, and production counts are included. This is processed further and displayed on a dashboard making it possible for you to monitor and manage the equipment's performance from the comfort of your couch.

Can I access the monitoring system remotely?

Undoubtedly, yes. The cloud-based system equips users with the flexibility of operating the dashboard from anywhere in the world with an internet connection. Apart from this, you can also visit it through mobile version which is really a relief to you since you can know what is going on with your machine from any device no matter where you are.

Contact Info:

Name: Pro Manage Cloud

Email: Send Email

Organization: Pro Manage Cloud

Website: https://promanagecloud.com/

Release ID: 89146188

Should you come across any errors, concerns, or inconsistencies within this press release's content, we urge you to reach out without delay by contacting error@releasecontact.com (it is important to note that this email is the authorized channel for such matters, sending multiple emails to multiple addresses does not necessarily help expedite your request). Our committed team will promptly address your feedback within 8 hours and take appropriate measures to resolve any identified issues or guide you through the removal process. Providing accurate and dependable information remains our utmost priority.